Many industries rely on frequency converters to stabilize power sources and maintain power-quality health. One key threat to power quality that affects workplaces using frequency converters is harmonic distortion. Harmonics are voltages or currents that are multiples of the fundamental frequency, usually 50 or 60Hz. They create distortions and negatively impact performance when above a certain threshold. We’ll explore three essential things you must know about frequency converter harmonics to ensure your facility runs smoothly.

Frequency Converters Can Introduce Harmonic Distortion

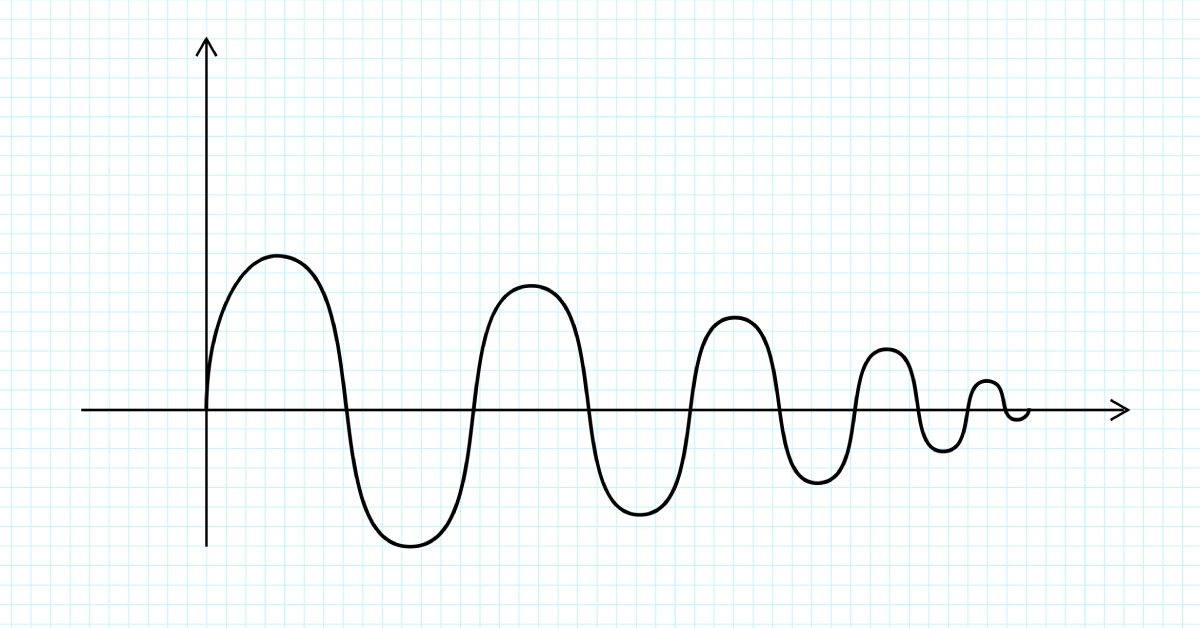

Frequency converters, while beneficial, can introduce harmonic distortion into electrical systems. This can occur when one voltage is in a non-sinusoidal waveform, causing it to become distorted. Devices such as frequency converters, which convert AC to DC power, and frequency inverters, which transform frequencies supplied to a motor, operate this way to maintain steady power.

Nonlinear loads directly introduce harmonics, which are multiples of the original frequency, into the supply network as they distort wavelengths to convert voltages. These additional frequencies can interfere with the normal operation of electrical equipment.

Harmonic Distortion Negatively Affects Power Quality

Harmonic distortion can severely impact power quality on a given supply network. Poor power quality results in unstable electrical systems, which can be detrimental to industrial operations. Devices connected to the affected power supply might operate inefficiently or even fail, leading to expensive repair costs.

The presence of harmonics can also lead to overheating in transformers and motors. This overheating can shorten the lifespan of these essential components and increase the risk of explosions as capacitors operate beyond their temperature threshold.

Harmonics Can Be Mitigated With Structural Changes

Fortunately, there are effective ways to mitigate the impact of harmonic distortion. One of the most efficient methods is to implement structural changes to your electrical system. These changes can help reduce or eliminate harmonics, improving overall power quality.

Installing harmonic filters is a common solution. Passive filters resonate at a particular harmonic frequency, typically between 250 and 350Hz, to intercept and minimize their effect on the supply network. Active filters measure currents and adapt to changing levels of harmonic distortion by generating harmonics in the opposite phase at a similar magnitude, effectively canceling harmful frequencies out.

Another effective strategy is to upgrade to higher-quality frequency converters with built-in harmonic mitigation features. Many modern industrial frequency converters come equipped with advanced technology to minimize harmonic generation. Investing in these high-quality converters can significantly reduce the occurrence of harmonic distortion.

Now you understand what you need to know about frequency converter harmonics. Visicomm Industries has supplied high-quality frequency converters for industrial applications for over 20 years. Our converters emit minimal harmonic distortion to ensure your facility operates smoothly and efficiently. Browse our product pages to learn more about our frequency converters and their performance specifications.